Supplemental lighting strategies that use LED grow lights use vast amounts of energy, and more than ever, growers must pay attention to energy costs in relation to the bottom line. Fortunately, by employing proactive measures, the energy costs associated with supplemental lighting can be carefully managed in relation to business needs. This article covers all of the best practices that professional cultivators use to contain lighting energy costs.

Use scheduling and dimming with your grow lights

Dimming your grow lights at specific times is a proven way to save energy with LED grow lights.

- Dim your lights to photoacclimate your crop during early stages of development

- Implement sunrise and sunset dimming schedules to ease your crop to drastic changes in light levels throughout the day

- Adapt your light levels to specific cultivars you are growing

Check out our Dimming & Energy Efficiency Growers Guide for more information.

Shop GrowFlux LED grow light dimmers & controls

Keep track of the peak energy consumption of your lighting system

The peak energy consumption of your grow lighting system is the maximum instantaneous power (measured in kilowatts) consumed by all of the lights simultaneously in your facility during your billing cycle (typically one month). This number is used to calculate your demand charge, which can make up a significant portion of your energy bill.

Some control systems can model the energy consumption of your systems. GrowFlux's app includes a whole facility energy analysis which can be used to compare your energy consumption and peak load to your rate structure.

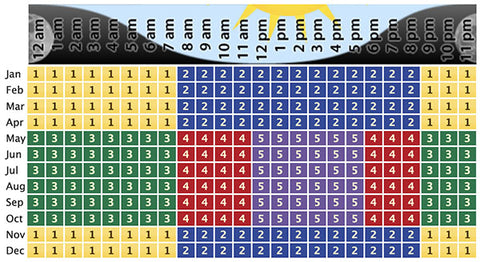

Dim your grow lights during peak energy rates

Most cultivators in North America have variable time of use (TOU) energy rate structures. If the timing of your energy rates is not clear on your utility bill, check your utility bill for the name of your rate structure, and research your rate structure on a tool like the Open EI Utility Rate Database.

Your grow light controls should be able to schedule a lower dimming level during select hours of the day.

Use a sunset dimming schedule to slowly dim to off at the end of the photoperiod

Some growers believe that a sunrise / sunset lighting control dimming schedule is a more natural way to light a crop. Setting that debate aside, using a sunset schedule will reduce your HAVC and dehumidification energy consumption. When the lights go from full intensity to off at the end of the photoperiod, the crop's stomata takes time to close. During the time that the stomata are closing, the crop is transpiring a significant amount of water, which translates to humidity. Not only can unnecessary humidity create a mildew risk, it also takes a lot of energy to remove.

Give your crop at least 30 minutes or longer to adjust to lights off by scheduling your dimming controls with a progressive dimming level.

Use PAR sensor based lighting controls in greenhouses

Greenhouses that use supplemental lighting may only need supplemental lighting during periods of significant cloud cover, during certain times of the day, or certain times of the season. Using a lighting control system that automates your lights based on light levels detected by a PAR sensor saves significantly more energy than manually adjusting lights each day or using timer based controls.

GrowFlux's Precision PAR® feature uses connected PAR meters to control your LED grow lights. Learn more

Select energy efficient grow lights

There is a wide selection of grow lights with very high efficiencies available, and you can verify the efficiency claims of a manufacturer by checking the product on the Design Lights Consortium Horticulture Qualified Products List. This list contains all of the DLC certified grow lights, along with the reported and tested metrics such as energy consumption and efficiency. Be sure to select lights that show at least 2.5 μmol/J efficiency as well as dimming capability. The DLC list can be difficult to navigate - chat with us if you need help!

Be aware that energy incentives for grow lights will require that you select DLC certified grow lights from the Horticulture Qualified Products List (QPL). In the future, controls incentives will also require DLC certified grow light controllers.

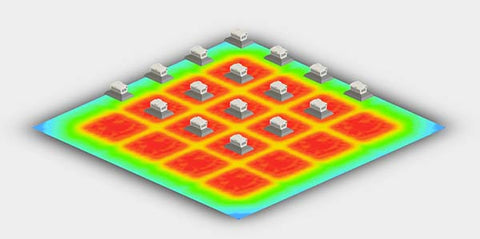

Ensure light from your grow lights is not wasted on floors, walls, or dark surfaces

Your grow lights will emit light primarily in one direction, however with most grow lights, there is a fair bit of low angle light that is emitted. Our article on coefficient of utilization goes into depth on this topic.

You can reduce stray light waste by employing the following tactics:

- Use light colored or white materials for walkways, floors, trays, and any area that is around or below the crop canopy. Using substantially white materials around your crop can boost light levels by as much as 12%

- Arrange your cultivation spaces in grids, so the low angle light from multiple lights falls onto your canopy. Avoid narrow rows of grow lights or placing individual grow lights far apart

- Understand the light distribution and recommended mounting height above the plant canopy for the specific light you are using. The manufacturer of your grow light should provide this information.

- Get a custom light plan from a grow light manufacturer that models your specific cultivation needs and light layout.

Take advantage of advanced energy savings with your utility company or with the help of an energy consultant

Every utility company offers different programs, including incentives and energy rebates, alternative rate structures, curtailment incentives, and demand response programs. Some programs may also generate revenue for your business for participating. Be sure to have regular conversations with your utility company a few times a year to stay on top of these opportunities.

In certain locations, energy consultants can help your business proactively reduce loads at select times throughout the year to qualify your business for a lower demand charge. Energy consultants can also help your business purchase energy up to 12 months in advance to save 15-40% on your electricity rates. GrowFlux offers these services at no upfront cost to commercial growers in the US and Canada - chat with us or contact us for more.